AUTOMATED PROFILE-BENDING COMPLEX PS –100

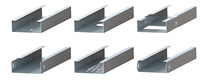

for manufacturing С –shaped profiles with a height 100 mm with a punching of assembly, fastening and communication holes.

Designation: manufacturing of truss roof and flooring constructions, internal partitions frameworks and external walls.

Usage: Construction of low-rise buildings and housekeeping areas.

Structure:

1. Power-driven unwinding device , console type for roll metal with a width not more than 450 mm. and weight up to 1,5 t.

2. Press for broaching holes ( 7 blocks 1 spare) with hydraulic drive. Executive devices for press tool block are made with hydraulic drives, program controlled.

(1) for anchor screws - ø 12,5, along profile axis.

(2) for communication lines - ø 52 mm. along profile axis.

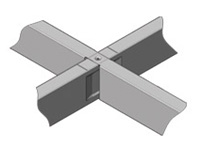

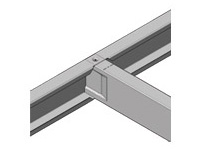

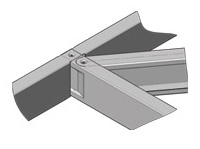

(3) Cut-through for a prop.(for С+С combination)

(4) Cut-out of shelves for a prop.

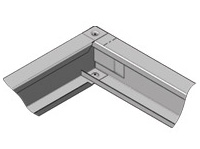

(5) Groove and 4 holes for fastening.

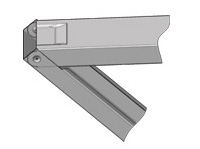

(6) Cutting of semi-circular tips for truss structures.

(7) Groove without holes

(8) One spare mounting seat

3. A device for shape marking (inscribing a logotype and assembly number). Marking device inscribes a marking for a profile according to control program.

4. Rolling mill with profiling rolls. Readjustment for another type of metal thickness is done manually by means of a device with a metric scale.

5. Compacting machine for pressing stud tips (hydraulic)

6. Cutting guillotine .(hydraulic)

7. Automatic control system.

Control program is formed by a specialized «Boracad» design program generating specification.

Total power consumption- 18 Kw.

Type of used metal:

Type of used metal:

Light-gauge roll metal galvanized by GOST Р 52246-2004.

Ϭ 0,2 = 220 – 350 Н/mm2

Metal thickness – 0,8-1,5 mm.

The range of construction profile heights – from 80 – 100 mm. (by option)

When ordering equipment profiling and punching tools are mounted for the size required by the customer form the offered catalogue.